to highlight the features, benefits, and advantages of my Stainless Steel Pin Mill.

Introducing the Stainless Steel Pin Mill – Your Ultimate Grinding Solution!

Are you tired of using traditional grinding machines that take a long time to finish the job and leave your final product with uneven particles? Do you want to upgrade your production process with a modern, efficient, and reliable grinding machine that guarantees a consistent grinding output? Look no further than the Stainless Steel Pin Mill – the ultimate grinding solution that promises to revolutionize your manufacturing process.

Our Stainless Steel Pin Mill is a top-of-the-line grinding machine that carefully grinds a wide range of materials, including chemicals, food ingredients, and pharmaceuticals products. With our Pin Mill, you can efficiently process any product with varying degrees of coarse or fine particles, such as powders, granules, or pellets.

Here are some of the amazing features and benefits of our Stainless Steel Pin Mill:

1. High-quality construction: Our Stainless Steel Pin Mill is made of top-quality stainless steel, which guarantees maximum durability, resistance to corrosion, and easy cleaning. The robust construction also allows for high-speed operation with minimal vibration and noise levels, ensuring a safe and comfortable working environment.

2. Precise and efficient grinding: Our Pin Mill features a unique design that ensures precise and efficient grinding with minimal product heat generation or loss. The pins rotate at a high speed, creating a strong impact that breaks up particles and produces consistent results regardless of the product's hardness or texture.

3. Easy to use and maintain: Our Pin Mill is designed for easy operation and maintenance. It comes with a user-friendly interface that allows you to customize the grinding conditions, such as grinding speed, pin configuration, and particle size. The Pin Mill is also easy to disassemble and clean, ensuring that it remains in excellent working condition and maintains its performance for longer.

4. Customizable designs: We understand that our customers have unique grinding needs and preferences, which is why we offer customization options to tailor the Pin Mill to your specific requirements. You can choose from a range of pin configurations, motor speeds, and other features to achieve the ideal grinding results for your products.

5. Energy-saving: Our Pin Mill features a unique design that is energy efficient and environmentally friendly. It requires minimal power to operate and produces less waste than traditional grinding machines, making it a cost-effective and sustainable solution for your production process.

6. Wide range of applications: Our Stainless Steel Pin Mill is suitable for a wide range of materials and applications, including grinding and milling of chemicals, food ingredients, and pharmaceutical products. It can also be used for recycling and upcycling of materials, making it a versatile and multipurpose grinding solution.

In summary, our Stainless Steel Pin Mill is a high-quality, efficient, and reliable grinding machine that guarantees consistent and precise grinding results for your products. With its robust construction, customizable designs, and energy-saving features, it is an ideal solution for any manufacturing process. Contact us today to purchase your Stainless Steel Pin Mill and take your production process to the next level!

Product Description

A particularly created mill, the stainless steel pin mill, can process a wide range of materials, from coarse to fine, up to 150 mesh (100 microns) and beyond, inexpensively and efficiently.

Product parameters

Model | Production Capacity | Feeding Size | Crushing Fineness | Spindle Speed | Crushing motor | Dust collecting motor | Discharge Motor | overall dimension | weight |

20BIV,V,VI | 60-150kg/h | 6mm | 20-120mesh | 4500 | 4kw | 2.2kw | 0.75kw | 3000*850*2300mm | 580kg |

30BIV,V,VI | 100-400kg/h | 6mm | 20-120mesh | 3800 | 5.5kw | 3kw | 0.75kw | 3200*850*2380mm | 880kg |

40BIV,V,VI | 160-1000kg/h | 10mm | 20-120mesh | 3400 | 11kw | 4kw | 0.75kw | 3500*900*2380mm | 1200kg |

60BIV,V,VI | 500-2000kg/h | 12mm | 20-120mesh | 2800 | 18.5kw | 7.5kw | 1.1kw | 6600*1100*2380mm | 2000kg |

80BIV,V,VI | 1000-5000kg/h | 15mm | 20-120mesh | 2200 | 37kw | 11kw | 1.5kw | 7800*1100*2500mm | 3000kg |

100BIV.V.VI | 2000-8000kg/h | 15mm | 20-120mesh | 1500 | 55kw | 18.5kw | 2.2kw | 9980*1280*2800mm | 6000kg |

Working principle

The stainless steel needle mill is composed of crusher, cyclone separator, pulse dust removal box, fan, etc. It crushes materials through the relative motion between the movable and fixed toothed discs, through the impact, friction and mutual impact of the teeth. The crushed material flows into the cyclone separator under the action of the gravity of the blower and the rotating centrifugal force, and then is discharged through the gate fan, and the dust enters the pulse dust box, and is filtered and recovered by the filter cartridge.

The crushing particle size can be adjusted through the screen. The whole machine is designed according to GMP standard, made of stainless steel, and there is no dust in the production process.

Application

Stainless steel needle mill is suitable for pharmaceutical, chemical, food, magnetic materials, powder and other industries. It is a new generation of crushing equipment that integrates crushing, dust collection and continuous discharge.

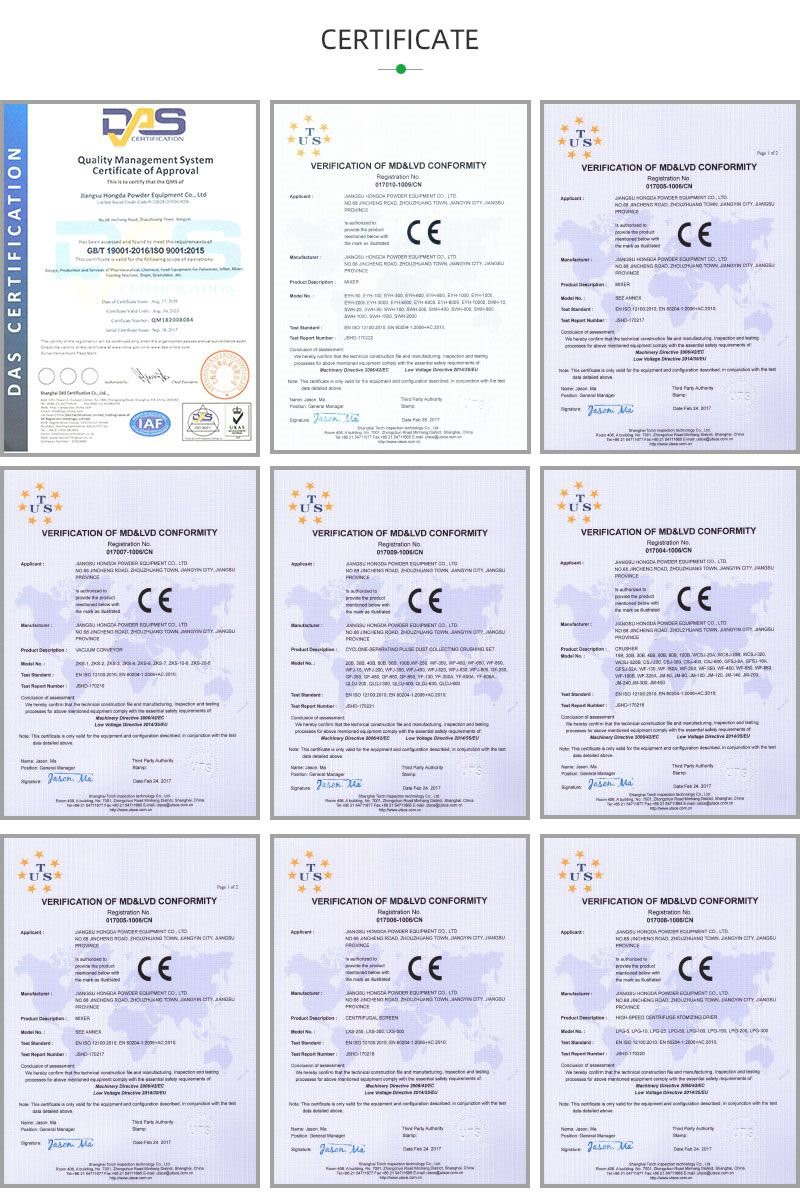

Why choose us?

- As a manufacturer and supplier of Universal Grinder, we have a strict quality control system to ensure that every product meets or exceeds industry standards.

- We promise to abide by all laws and regulations, and be responsible for our words and deeds, fulfill our duties and strive for performance and achievements.

- We have a team of professionals who are dedicated to producing the finest quality Universal Grinder products.

- We hope to achieve high-quality super-regular leap-forward development of the company through innovation-driven, industry-linked and management-driven.

- Our Universal Grinder products are easy to install and integrate into existing systems, minimizing disruptions to our customers' operations.

- We will always adhere to the concept of soundness and balance the relationship between development, risk and profitability.

- Our Universal Grinder products are made to withstand harsh environments and extreme conditions, ensuring they remain durable and reliable.

- In order to meet the needs of customers, the company is committed to improving the functions and improving the quality of Stainless Steel Pin Mill products, and has built a diverse operating industry group with diverse formats and industries.

- We are committed to providing our customers with exceptional value for money, delivering high-quality Universal Grinder products at competitive prices.

- Our development vision is to become a people-oriented friendly, dynamic and efficient enterprise.

Hot Tags: stainless steel pin mill, China stainless steel pin mill, Stainless Steel Pin Mill, Stainless steel coarse crusher, Pin Mill Pulverizer, mirchi grinder machine, grinder machine commercial, Hammer Mill Machines

Previous

Pin Mill Pulverizer